Why every country needs to master the Electric Tech Stack

The industries you need for national defense are also the industries you need for manufacturing...everything.

The other day I gave a talk at a conference in Canada about industrial policy. When we came to the inevitable question of which specific industries Canada should target, I had an answer ready: “the Electric Tech Stack”.

The fact that I had an answer ready surprised some people in the audience. The traditional criticism of industrial policy is that it’s all about “picking winners”, and that winners are very hard for even the smartest person to pick. But in some cases it’s actually very easy to pick winners. In the 19th century, every country knew they needed railroads, both for national defense and for transporting goods. In the 20th century, many countries knew they needed an auto industry, because those same assembly lines and supply chains could be quickly repurposed to make tanks and other military vehicles in case of a war. In the early 20th century, countries knew that having a steel industry was crucial for creating most of the important military equipment, while in the later century, the U.S. correctly guessed that having a powerful semiconductor industry was crucial for dominance in precision weaponry.

In all four of these cases, there were arguments about the economic benefits of promoting the industries in question, but in the end it was military necessity that tipped the balance decisively in favor of industrial policy. As I told the folks in Canada, a similar thing is true in the 2020s.

In the mid 19th and early 20th centuries, railroads won wars by letting countries move supplies rapidly to the front. In the mid 20th century, wars were won by the countries that could produce lots of military vehicles like tanks and planes. In the early 21st century, the ability to win wars relies on being able to produce lots of drones.

Just a few years ago, my amateurish prediction that drones would dominate the modern battlefield was often met with a combination of amusement and scorn. Then the Ukraine War came along, and what had seemed like a crank prediction became conventional wisdom in just a few years. Every serious observer now recognizes that drones are the essential weapon of modern warfare. These little battery-powered toys are defeating infantry and armored vehicles alike. IFRI reports:

[T]he Russian invasion of Ukraine has become the theater of a massive drone-driven transformation of military operations. This phenomenon is unprecedented, both in quantitative terms—with several million drones now produced and destroyed each year—and in its influence on the dynamics of operations and the structure of forces. For context, the most drone-intensive conflict prior to 2022 was the war over Nagorno-Karabakh, where drones were responsible for around 45% of all losses in armored vehicles, artillery, and air defense systems. In Ukraine, by 2025, drones are estimated to account for 60 to 70% of all losses across all categories.

For both belligerents, drones have thus become the primary sensors, relays, and [weapons]. They constitute a robotic and increasingly automated nervous system that shapes fire support and movement coordination across all domains and operational environments…[D]rones serve simultaneously as binoculars, grenades, and mortars for infantry, who continuously reconfigure them to adapt to the enemy. They have also taken a central role in counter-battery fire, deep reconnaissance, and battlefield interdiction—roles traditionally reserved for Army aviation. At a strategic depth, they are reshaping methods of penetrating air defenses and, through cost-effective mass deployment, they are enabling maneuvering salvos against critical, economic, and political targets central to the adversary’s war effort.

More fundamentally, drones have allowed both the Ukrainian and Russian armies to maintain coherence and combat effectiveness under extreme attrition in personnel and heavy equipment. They provide the shock element needed for offensive thrusts and the stopping power required to hold or retake positions. In this sense, drones saturate the front lines like a permanent grapeshot or a reactive shield against enemy breakthroughs. They infiltrate and prowl the rear areas, hunting fire support assets and logistics, posing a constant threat to any troop or equipment rotation. They also conduct long-range raids against infrastructure and troop concentrations. [emphasis mine]

And this is all before autonomous AI-controlled drone swarms enter the battlefield in force, as everyone now expects them to do very soon.

So if you want to be able to defend your country against attack in the 21st century, you really need to be able to either make large amounts of drones yourself, or reliably procure them from a country that you know will sell them to you at a reasonable price during wartime. And if you want to be able to make drones, you also need to be able to make or reliably source the materials and components that go into a drone. In fact, drones aren’t very hard to assemble, so controlling the supply chains for those materials and components is actually the whole ball game.

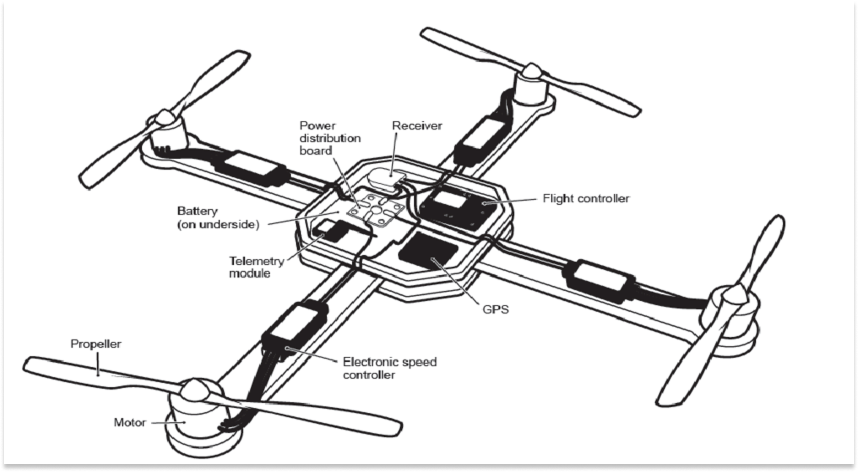

What are the parts that make up a drone? Some of it is stuff like injection-molded plastic, but that’s easy. If you look at a diagram of what goes into a drone, like the one at the top of this post, you can see what the actually important components are. They are:

1. A lithium-ion battery, to power the drone

2. Some permanent-magnet electric motors, to make the propellers move

3. Some power electronics in the power distribution board and the electronic flight controllers — to turn power from the battery into a form the motors can use

4. Some trailing-edge computer chips, in the receiver, the telemetry module, the flight controller, etc.

Everyone already knows about the importance of the chip industry, and chips have been militarily important for a very long time now. But the importance of the first three — batteries, electric motors, and power electronics — is new. I now refer to these three items as the Electric Tech Stack.

If you want to be able to defend your country, you simply have no choice but to secure the Electric Tech Stack. And this includes securing the minerals that are necessary to create the Stack, especially rare earths like neodymium and other minerals like gallium. If you don’t do this, you are perpetually at risk of having your drone supply cut off, which will cause you to rapidly lose any modern war.

This is the first key fact about the Electric Tech Stack. The second key fact is that if you can master it, you can master a wide variety of modern manufacturing industries as well.

The Electric Tech Stack is the key to modern manufacturing

A few months ago, I interviewed Sam D’Amico, the founder and CEO of Impulse Labs,1 about how the U.S. can win back manufacturing:

Sam — who is one of the best engineers I’ve ever met — argued that there is now a suite of just a few core technologies that are the key to manufacturing an increasingly wide array of products. In the past, manufacturing industries were very differentiated — making a car, an airplane, a telephone, a TV, and a stove all involved very different production processes and very different supply chains. Being able to manufacture cars didn’t really make you able to manufacture TVs, or vice versa.

According to Sam, that’s changing as we speak. Electric motors are overtaking combustion engines as the fundamental technology that makes machines move. This means that the same supply chains and production processes that allow you to make electronics will now also allow you to make cars, drones, motorcycles, robots, appliances, and a bunch of other products.

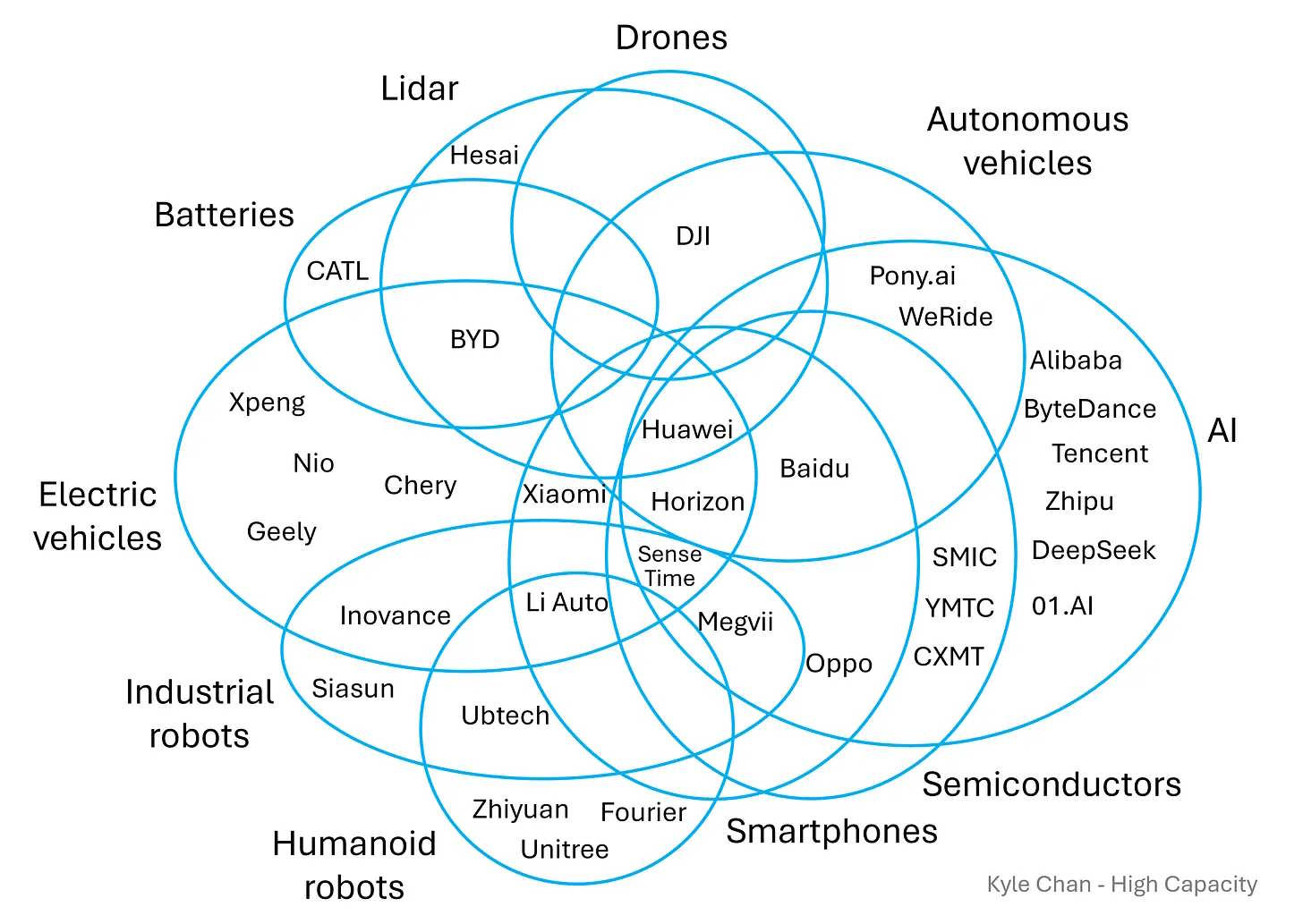

This is why a company like Xiaomi, which makes phones and other electronics, was able to become one of China’s top EV manufacturers in short order — making a phone is no longer that different from making a car. And it’s why BYD is now arguably the world’s #1 manufacturing company. The more different products you make that use the Electric Tech Stack, the more you can harness economies of scale and drive prices lower, thus securing market dominance.

Kyle Chan had a great post about China’s top companies back in January, in which he drew a helpful diagram:

The list of technologies that these companies target corresponds very well to the Electric Tech Stack.

In recent weeks, more people from the tech world have begun vocally recognizing the importance of the Electric Tech Stack. Ryan McEntush of Andreessen Horowitz wrote a great post about it:

[We] need a bridge that truly connects bits to atoms.

That bridge is the electro‑industrial stack — the technologies that enable machines to behave like software: minerals and metals processed into advanced components, energy stored in batteries, electrons channeled by power electronics, force delivered by motors and actuators, all orchestrated by software running on high-performance compute…

The electro-industrial stack is changing how we build and run machines…Electrified systems, built on batteries, power electronics, and high-torque motors, are more efficient, more precise, and more responsive to software. They can be tested in simulation, updated over the air, and improved continuously as telemetry feeds back into design…In other words, with the electro-industrial stack, physical machines are beginning to behave like software…

The electro-industrial stack is the bridge between software and the physical world, the foundation animating the machines that will ultimately shape the future…No company illustrates this power more clearly than BYD. What began as a Chinese battery maker now dominates the global EV market and extends into cargo ships, trains, buses, and industrial equipment. BYD even supplies more than half of DJI’s drones, by some accounts. This breadth is possible because its products share the same core technologies in which BYD has built deep expertise — mineral sourcing and refining, batteries, motors/actuators, power electronics, compute, and final assembly.

We should not aim to build an “American BYD”, but we must create its equivalent through an ecosystem of integrated suppliers and OEMs[.]

McEntush makes an excellent point that I had missed, which is that electric tech products interface with software more easily than did old combustion-engine or analog technologies.

Back in May, Daan Walter, Sam Butler-Sloss, and Kingsmill Bond wrote a great post arguing that Western countries have been slow to embrace the Electric Tech Stack because they’ve insisted on seeing it as a climate issue rather than being about national defense, manufacturing industries, and cheap power:

And the best (and longest) post about the Electric Tech Stack was written by Packy McCormick, who worked with Sam D’Amico to produce an epic explainer about modern electric technology and why it’s taking over:

This “post” is basically a short book, but it’s worth reading. It explains:

How each piece of the Electric Tech Stack works, and why it will inevitably take over more and more industries

Why AI dominance will also depend on mastering the Electric Tech Stack

Why China now controls most of the Electric Tech Stack, even though the key technologies were mostly invented in America or Japan

Some ideas for how the U.S. can build the Electric Tech Stack domestically

Packy makes another key point that I left out above, about the connections between electric tech and AI. AI takes a huge amount of electric power; solar and wind are the cheapest power sources, but they require batteries to smooth out their intermittency. In other words, supremacy in the software industry in the 21st century will probably require a strong presence in (electric) physical industry as well.

I’ll talk more in a later post about the specific industrial policies that countries can take in order to build up their Electric Tech Stack. For now, I just want to emphasize two key points:

Drones are the key to hard power in the early 21st century. If your country can’t make drones, you’re in trouble.

If you have the ability to make drones domestically, you can also manufacture an increasingly large percentage of everything else.

These two points make it clear what kind of industrial policy government should be pursuing right now. Promoting the Electric Tech Stack is crucial for national defense. Fortunately, it’s also helpful for growing new manufacturing industries.

In this situation, we don’t need to tear our hair out asking which industries the government should promote; as in the era of the railroads, the answer is bleedingly obvious. A core set of “winners” has already been picked for us — it’s just batteries, electric motors, power electronics, and chips.

This is a lesson China has learned, and the West has not yet learned.

Disclosure: I invested in Impulse Labs.

Great post - very eye opening stuff. One nuance is that the power electronics requirements needed for EVs and electric trucks are a couple of orders of magnitude bigger than those used for drones. The biggest drones need a few kw of power delivery from the battery while performance EVs can need up to a MW of instantaneous power. Voltages go from 12-50 volts on most drones to 800 volts or more for basic EVs. That level of scaling changes the problem so much that it's really a different skill set. So it's essential the US has knowhow and manufacturing capability to make high power electronics and this likely means a strong domestic EV industry.

Also, Noah touched on this, but imo energy production is another critical industry for both economic and military power where the tech is changing fast and where we've fallen behind in industrial capability. Obviously batteries and renewable tech will be essential to maintaining a competitive electro-stack, but the ability to manufacture high voltage transformers and boring power grid tech can't be ignored. I was glad to see Tesla is planning to start manufacturing its own high voltage transformers (I think for EV chargers). With the current 2-4 year lead times on some of this stuff, we're reminded that this boring industrial tech is essential and can be a limiting factor in electro-stack dominance.

Finally, and this one is a little out there, another electro-stack tech with break out potential is nuclear tech, especially SMRs and micro-reactors that can also be used for military purposes. This stuff isn't nearly as far along as drones and EVs, but it could be disruptive if it can be made to work and I think breakthroughs in small and mobile nuclear tech would have big military implications.

Interesting post.... the electric "stack" is certainly pretty important. I would add to this.... an accompanying software/AI "stack." These two actually interplay with each other. The US has naturally drifted up to the SW/AI "stack" because the business margins are much better. China has drifted into and is now dominating the HW electric stack...although most of the companies in the China circle are struggling with business profitability. The world wants a pseudo standard cheap/scalable HW platform on which one can differentiate with SW/AI.

Overall, the key challenge for the US is .... how does one build incentives to invest in a naturally lower margin HW business ? How does one do so when another country is further subsidizing an already lower margin business ? One can do one offs in the name of national security, but that is not too sustainable. The likely solution is effective robotization where the cost-of-labor is a more minimal factor.... we need some more innovation to get there.